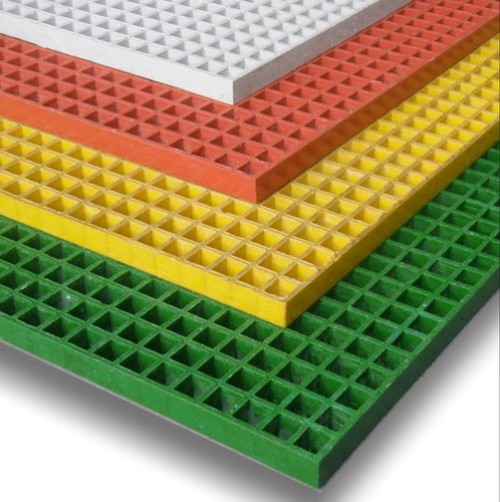

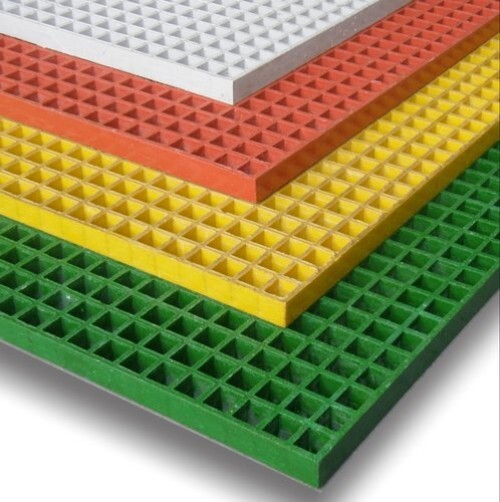

INDUSTRIAL FIBER GLASS GRATING

INDUSTRIAL FIBER GLASS GRATING Specification

- Length

- 1000 mm, 2000 mm, 3000 mm, 4000 mm, (Custom Length Available)

- Height

- 25 mm, 30 mm, 38 mm, 50 mm, (Custom Height Available)

- Shape

- Rectangular, Square

- Product Type

- Industrial Fiber Glass Grating

- Material

- Fiberglass Reinforced Plastic (FRP)

- Application

- Walkways, Platforms, Chemical Plants, Food Processing, Marine, Oil & Gas

- Surface Treatment

- Anti-slip Coated, Smooth, Gritted

- Size

- Standard and Custom Sizes Available

INDUSTRIAL FIBER GLASS GRATING Trade Information

- Minimum Order Quantity

- 1000 Meter

- FOB Port

- VADODARA

- Main Domestic Market

- All India

About INDUSTRIAL FIBER GLASS GRATING

INDUSTRIAL FIBER GLASS GRATING

Industrial Fiberglass Grating: Benefits and Applications

Industrial fiberglass grating, made from fiberglass reinforced plastic (FRP), offers significant advantages across various industries. Here are key points to consider:

1. Corrosion Resistance

Fiberglass grating excels in harsh environments, resisting corrosion from chemicals and moisture. It's perfect for industries such as chemical processing and marine applications.

2. Lightweight and Easy to Handle

This grating is notably lighter than steel, reducing transportation costs and making installation easier without compromising strength.

3. Strength and Durability

Despite its lightweight nature, fiberglass grating is robust and durable, capable of withstanding heavy loads and impact.

4. Non-Conductive and Safe

It's non-conductive and doesn't conduct electricity, ensuring safety in environments with electrical equipment.

5. Low Maintenance

Requires minimal upkeep compared to materials like steel, as it doesn't rust or corrode.

6. Slip Resistance

Textured surfaces provide excellent slip resistance, even when wet, ensuring safety in industrial settings.

7. Fire Retardant Properties

FRP materials used are inherently fire retardant, meeting stringent safety standards.

8. Versatility in Applications

Available in various sizes, colors, and configurations to suit specific industrial needs, including oil and gas, pulp and paper, and food processing.

Why Choose Fiberglass Grating?

Fiberglass grating combines durability, safety, and versatility, making it an ideal choice for industries requiring reliable, long-lasting structural solutions.

For more information on how fiberglass grating can benefit your industry, contact us today.

Exceptional Load and Safety Performance

Engineered to bear heavy loads up to 5 tons per square meter, our fiberglass gratings guarantee both structural integrity and user safety. The panels are non-conductive and fire retardant, meeting ASTM E-84 standards, ensuring protection in hazardous environments. Enhanced with anti-slip coatings and available in various surface finishes, they minimize the risk of workplace accidents.

Corrosion-Resistant and Weatherproof

Designed for harsh industrial settings, this grating offers exceptional resistance to chemicals, moisture, and UV radiation. Unlike metal alternatives, FRP gratings remain rust-proof, making them highly suitable for outdoor and marine environments. These properties extend the product's lifespan and reduce replacement costs, supporting uninterrupted operations.

Flexible Designs and Easy Installation

Available in a range of mesh sizes, heights, lengths, and custom configurations, the grating can be tailored to unique project requirements. Lightweight panels simplify transport and installation, minimizing downtime. Choose from green, yellow, grey, or custom colors to match your application and safety standards. Multiple surface treatments ensure the perfect finish for any industrial use.

FAQ's of INDUSTRIAL FIBER GLASS GRATING:

Q: How does industrial fiberglass grating benefit facilities in corrosive environments?

A: Fiberglass grating is corrosion-resistant, maintaining structural integrity even in extreme chemical, marine, and damp conditions where metal grating would typically fail. This helps reduce maintenance needs and extends service life, making it ideal for chemical plants, food processing, and marine applications.Q: What is the process for installing fiberglass grating panels?

A: Fiberglass grating panels are lightweight and can be cut on-site for precise fitting. They are easily placed onto support frames and secured with clamps or fasteners, eliminating the need for heavy equipment or specialized installation techniques. This streamlines the setup and reduces labor costs.Q: When should I choose fiberglass grating over metal alternatives?

A: Fiberglass grating is preferable when corrosion, electrical conductivity, and long-term low maintenance are critical factors. Its non-conductive and rust-proof nature provides distinct advantages in chemical, electrical, and outdoor environments compared to steel or aluminum grating.Q: Where can this fiberglass grating be used?

A: This grating is suitable for walkways, platforms, ramps, trench covers, and equipment shelters in sectors such as chemical processing, food and beverage plants, oil & gas facilities, marine docks, and wastewater treatment plants.Q: What customization options are available for your fiberglass grating?

A: We offer a variety of colors, mesh sizes (standard or custom), panel sizes, surface treatments (anti-slip, smooth, gritted), shapes (rectangular, square), heights, and lengths to meet specific project requirements. Unique designs can be accommodated upon request.Q: How does the anti-slip surface improve safety?

A: Anti-slip coated or gritted surfaces significantly enhance traction, particularly in wet or oily conditions, reducing the likelihood of slips and falls. This is especially important in industrial settings with heavy foot traffic and potential hazards.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in FRP Gratings Category

Fiberglass grating

Price 360.0 INR / Unit

Minimum Order Quantity : 100 Units

Product Type : FRP Grating

Color : Yellow , Green , Red

Material : Fiberglass

Usage : Industrial , Swimming Pool , Floor , Walkway

Composite grating

Price 365.0 INR / Unit

Minimum Order Quantity : 10

Product Type : FRP Grating

Color : Yellow , Red, Green , Black

Material : Fiberglass

Usage : Industrial

FRP Grating

Price 360.00 INR / Meter

Minimum Order Quantity : 10 Units

Product Type : FRP Grating

Color : Yellow, Green , Black, Red

Material : FRP

FRP Gratings For Oil and Gas Plant

Price 1100.00 INR / Square Meter

Minimum Order Quantity : 50 Square Meters

Product Type : GRATING

Color : YELLOW

Material : Fiberglass

Usage : OIL AND GAS PLANT