Drainage Cover FRP Grating

Drainage Cover FRP Grating Specification

- Shape

- Rectangular or Square

- Height

- 25mm - 50mm (as per requirement)

- Length

- 1000mm - 3000mm (as per requirement)

- Usage

- Drainage

- Material

- FRP

- Application

- Drainage Cover for Drain Systems

- Product Type

- Drainage Cover FRP Grating

- Surface Treatment

- Painted

- Size

- Custom/Standard sizes available

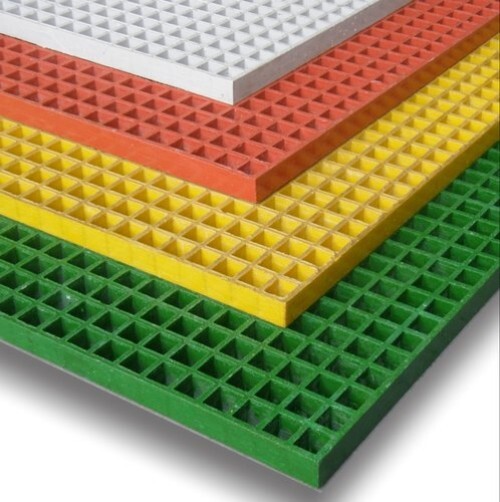

- Color

- Grey

- Maintenance

- Low maintenance requirement

- Open Area

- Optional (customizable grating spacing)

- Slip Resistance

- Anti-slip surface

- Fire Resistance

- Yes

- Service Life

- Long lasting (over 20 years)

- Weight

- Lightweight

- Load Bearing Capacity

- Heavy/Medium Duty Rated

- UV Resistant

- Yes

- Installation Method

- Modular, Easy to Install

- Compliance

- Meets IS & international standards

- Water Absorption

- Negligible

- Corrosion Resistance

- Excellent

Drainage Cover FRP Grating Trade Information

- Minimum Order Quantity

- 100 Pieces

- Supply Ability

- 1000 Pieces Per Day

- Delivery Time

- 10 Days

- Main Domestic Market

- All India

About Drainage Cover FRP Grating

Drainage Cover FRP Grating .

FRP (Fiber Reinforced Plastic) grating is a type of grating made from a composite material consisting of a polymer matrix reinforced with glass fibers. FRP grating is known for its corrosion resistance, lightweight nature, and high strength-to-weight ratio. It is commonly used in various industries, including wastewater treatment plants, chemical processing facilities, and other environments where traditional materials may corrode or degrade.

If you are looking for a drainage cover made of FRP grating, it is likely to be used in areas where drainage is essential, such as industrial floors, platforms, or walkways. The use of FRP grating for drainage covers offers several advantages, including:

Corrosion Resistance: FRP is highly resistant to corrosion, making it suitable for environments where exposure to chemicals or moisture is a concern.

Lightweight: FRP grating is lightweight compared to traditional materials like steel, making it easier to handle during installation.

High Strength: Despite being lightweight, FRP grating has a high strength-to-weight ratio, providing structural integrity while supporting heavy loads.

Durability: FRP grating is durable and can withstand harsh environmental conditions, including exposure to UV radiation.

Non-Conductive: FRP is a non-conductive material, making it suitable for use in electrical environments where conductivity is a concern.

Low Maintenance: FRP grating requires minimal maintenance and is easy to clean, contributing to its cost-effectiveness over time.

When selecting an FRP grating for a drainage cover, consider factors such as the mesh size, load-bearing capacity, and the specific requirements of the environment in which it will be installed. Additionally, FRP grating can be customized to meet specific design and size requirements.

Its important to consult with the manufacturer or supplier to ensure that the chosen FRP grating meets the necessary specifications for your drainage cover application.

Exceptional Durability and Performance

Engineered to withstand harsh environments, this FRP grating combines heavy or medium-duty load bearing capabilities with excellent resistance to corrosion, UV rays, and fire. Its robust construction ensures a service life extending beyond two decades, making it highly reliable for critical drainage cover applications.

Easy Installation and Customization

The gratings lightweight modular design makes installation straightforward, saving time and reducing labor requirements. Customizable open area, height, length, and shape options let you tailor the product to fit any drainage system perfectly, enhancing its versatility for varied project needs.

Low Maintenance and Compliance

With a negligible water absorption rate and anti-slip painted finish, this FRP grating is exceptionally low-maintenance. It meets IS and international standards, offering peace of mind for compliance and safety in public or industrial drain systems across India.

FAQs of Drainage Cover FRP Grating:

Q: How is the FRP drainage cover installed?

A: The FRP drainage cover utilizes a modular system, making installation simple and efficient. Its lightweight nature allows for easy handling, and the panels can be fitted to standard or custom dimensions, significantly reducing installation time and effort.Q: What makes this grating suitable for heavy or medium-duty applications?

A: This FRP grating is engineered for high load-bearing capacity, making it ideal for both heavy and medium-duty settings. Its robust fiberglass construction maintains structural integrity under traffic, ensuring safety and longevity.Q: When should I consider using FRP grating over traditional materials?

A: FRP grating is preferable when you require excellent corrosion resistance, UV stability, fire safety, and long service life with low maintenance. Its especially effective in environments exposed to chemicals, moisture, or outdoor elements where metal or concrete may degrade faster.Q: Where can this drainage cover be applied?

A: This FRP grating is suitable for a wide range of drainage systems, including industrial plants, commercial properties, public infrastructure, or residential complexes. Customizable sizing and anti-slip features make it adaptable for both indoor and outdoor installations.Q: What is the process for customizing FRP grating dimensions or open area?

A: Customization is available for grating spacing, height (25mm50mm), length (1000mm3000mm), and overall shape (rectangular or square). You can provide your specific requirements, and the manufacturer will fabricate grating that matches your drainage cover needs.Q: How does the anti-slip surface benefit users?

A: The painted anti-slip surface minimizes the risk of accidents in wet conditions, providing safety for pedestrians and maintenance staff. This makes it particularly effective for use in public walkways, factory premises, or other potentially slippery environments.Q: What maintenance is required for this drainage cover?

A: Thanks to its negligible water absorption, corrosion resistance, and UV protection, maintenance needs are minimal. Regular cleaning to remove debris is typically sufficient to keep the grating functional and visually appealing.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in FRP Gratings Category

FRP Grating Manufacturer

Price 360.0 INR / Unit

Minimum Order Quantity : 10

Usage : INDUSTRIAL

Material : FRP

Product Type : FRP Grating

Color : Yellow, Green , Black, Red

Fiberglass grating

Price 360.0 INR / Square Foot

Minimum Order Quantity : 100 Units

Usage : Industrial , Swimming Pool , Floor , Walkway

Material : Fiberglass

Product Type : FRP Grating

Color : Yellow , Green , Red

Molded FRP grating

Price 360.00 INR / Meter

Minimum Order Quantity : 10 Pieces

Usage : Industrial , Solar

Material : FRP

Product Type : FRP Grating

Color : Yellow, Green , Black, Red

FRP Gratings for Air Treatment Plants

Price 5900.0 INR / Piece

Minimum Order Quantity : 100

Usage : Industrial

Material : Fiberglass

Product Type : FRP Gratings

Color : Yellow Grey